Hand Press Die (Spring Snaps L No.8050) HASI HATO

Spring Snaps (Hand Press Dies)【HASI HATO】

Item Name

Hand Press Die (Spring Snaps L No.8050) HASI HATO

Size

Spring Snaps (L No.8050) Hand press die exclusively for HASI HATO

Use

Dedicated dies to be attached to a hand press machine.

Anyone can easily install metal fittings without making noise.

【HASI HATO】This is a die for a hand press machine of metal fittings.

Characteristics

This product is a die exclusively for HASI HATO's hand press machine.

【HASI HATO】is a long-established Japanese metal fittings manufacturer established in 1925.

For about 100 years, it has been used for high-end accessories, bags, and leather goods in Japan and abroad.

Therefore, its durability and quality are second to none.

HASI HATO is a manufacturer whose tool designs we have matched with our own.

Therefore, we have no trouble with incompatibility of setters and metal fittings.

You can use this service with peace of mind.

There are many manufacturers of metal fittings in the world.

Some people may not care about the quality of the metal fittings, thinking, "It's just for fastening leather, isn't it?

You may not usually look at the quality of metal fittings from the perspective of a metal product.

In fact, metal fittings are not the same at every manufacturer.

We select and sell [high-quality, low-priced hardware made in Japan] from the viewpoint of [leather craft tool manufacturer].

We make tools to the standards of reputable metal fittings manufacturers.

This is the best way to ensure trouble-free use.

Hand press dies sold on the Internet and other retailers range from inexpensive to expensive.

The common feature is that there is no mention of "which metal fittings manufacturer the tool was made for".

Since we are the manufacturer, we know [which metal fittings manufacturer the tool was made for].

That's why we clearly state the information.

In manufacturing this time, we reviewed from scratch the hand press dies sold in the world.

We have created this product by considering "what is good and what is bad" from the viewpoint of our factory specializing in leather craft.

We were particular about [four points].

1. Metal fittings are to be numerically converted into drawings and tools are to be made.

2. To eliminate rough dimensional tolerances and unify with the standards of domestic hand press machines.

3. Metal fittings must be mirror finished to prevent scratches.

4. To make a tool that can be stopped by hand with a special Setter for Upper Die.

【Characteristics】

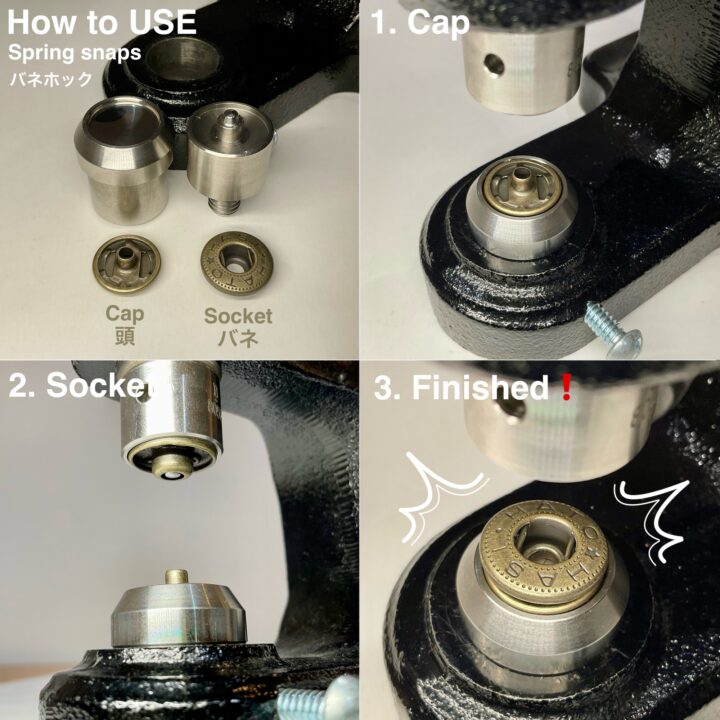

1.【Metal fittings are to be numerically converted into drawings and tools are to be made !】

The first thing we did was to quantify metal fittings.

HASI HATO" has been making metal fittings for 100 years.

“HASI HATO" Metal fittings have been refined and sharpened over a long period of time, and are the final, finished form that we have finally arrived at.

By quantifying the long history, we can for the first time make tools that match the Metal fittings.

2.【To eliminate rough dimensional tolerances and unify with the standards of domestic hand press machines !】

In this project, we measured the dimensions of hand press dies from various other manufacturers.

As a result, we found that the same product has different dimensions and is not a uniform standard.

Our products, both Upper die and Lower die, are made to the dimensional specifications of Japanese hand press machines.

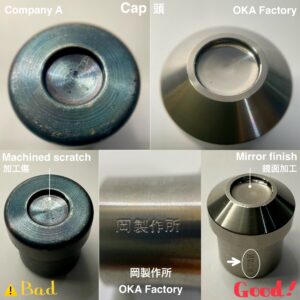

3.【Metal fittings must be mirror finished to prevent scratches !】

As shown in the image, the lower die of another company's product has machining scratches.

Because the round bar (material) is rotated and processed, processing scratches will inevitably occur.

When the metal fittings are stopped, these scratches are "left as scratches on the metal fittings".

Our products are dedicated to mirror finishing of lower die for Cap.

The lower die is free of any machining scratches, so it can be installed as it is with the original beauty of metal fitting.

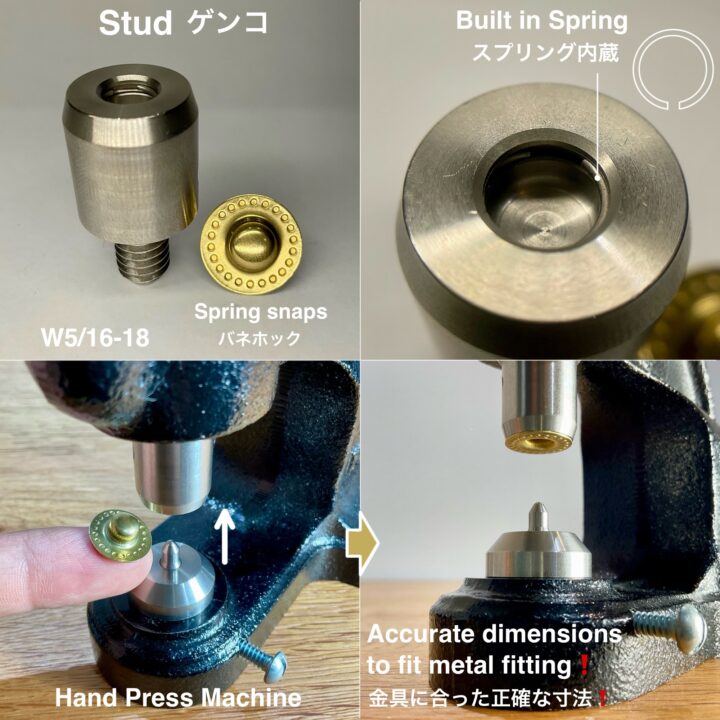

4.【To make a tool that can be stopped by hand with a special Setter for Upper Die !】

It is very time-consuming to use a Hand Press machine to stop a small number of Rivets metal fittings.

We created "Upper die setter" to eliminate this hassle.

We were particular about "four points.

① The entire product is subjected to a "hardening process" to improve wear resistance.

② Setter should be 15 mm thick.

Thick enough to absorb the impact of the upper die when struck and firmly stop the metal fittings.

Thickness to match W5/16-18 thread standard.

③The handles are non-slip so that work can be performed securely.

④The entire surface is plated to prevent rust.

You can easily stop the fittings by placing "Anvil (6sizes) or Anvil" underneath.

*Hand press dies are made to the dimensions of steel metal fittings.

When brass metal fittings are used, the curl of the pipe may crack and stop.

This phenomenon is caused by the difference in metal properties and rigidity between iron and brass.

Even if the pipe breaks, there is no problem with strength and durability in use.

Please use with understanding.

*Never use the lower die when hand hammering !

Lower die is not a tool designed to be stopped by hand.

Lower die is not designed to withstand the impact of striking.

Striking by hand with the Lower die by force will cause deformation.

Usage & Maintenance

-

User's Manual

-

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661