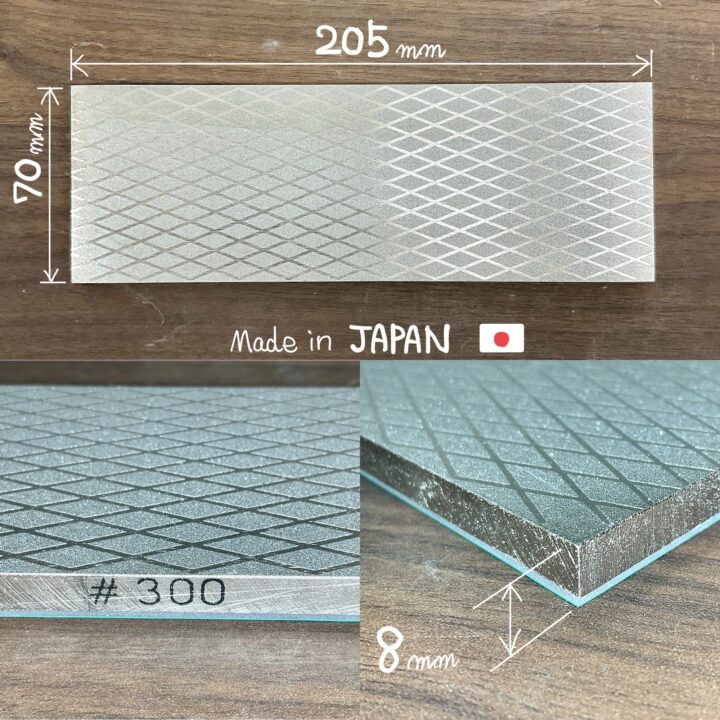

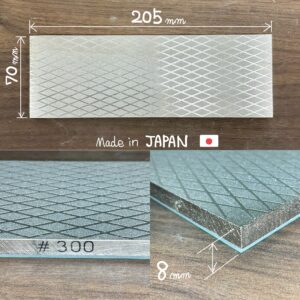

Rough Sharpening Stone #300

Item Name

Rough Sharpening Stone #300

Size

Grid number/#300・Size/205mm×70mm×8mm

Use

(1) Rough sharpening of knives (leather knives, cooking knives, knives, carving knives, chisels, planes, hammered blades, precision knives, etc.)

(2) Resurfacing of whetstones (*Roughening of whetstones that have been dented by edge sharpening)

(3) A wide range of materials can be polished, including hardened steel, cemented carbide, ceramic, HSS, and stainless steel.

Characteristics

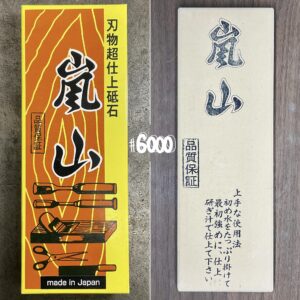

Water sharpening stone" was selected from among many sharpening stones by the connoisseur of "leather tool factory(OKA Factory)".

We selected this stone in consideration of price, quality, durability, and ease of use.

All three types of sharpening stones are made in Japan.

Many people seem to think that sharpening blades is difficult, but it is not difficult at all.

If you follow the order of sharpening, including the type of sharpening stone, preparation, and angle of the blade, as shown in the images on our website, you will surely get a sharp blade.

Our Skiving knife is also sharpened with the same sharpening stone.

Please refer to our Instagram video for more information on how to sharpen your knives.

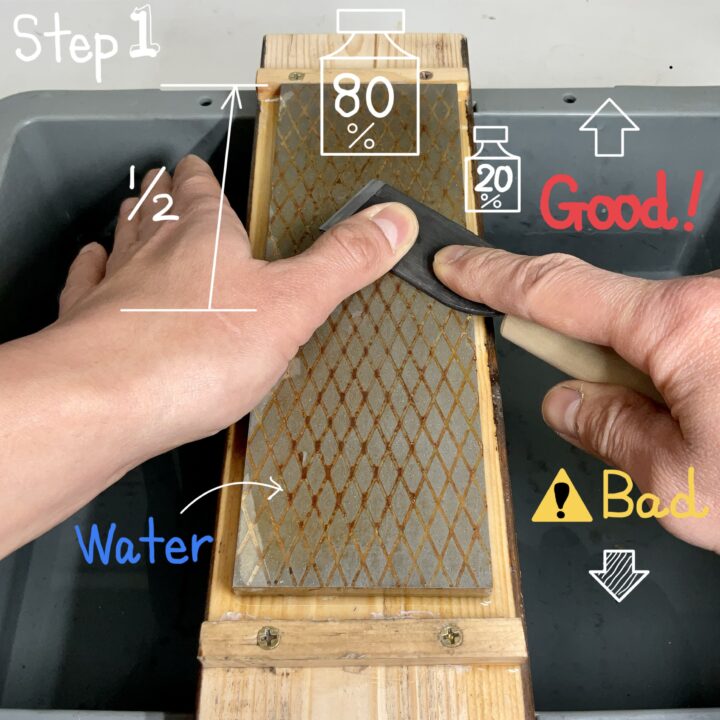

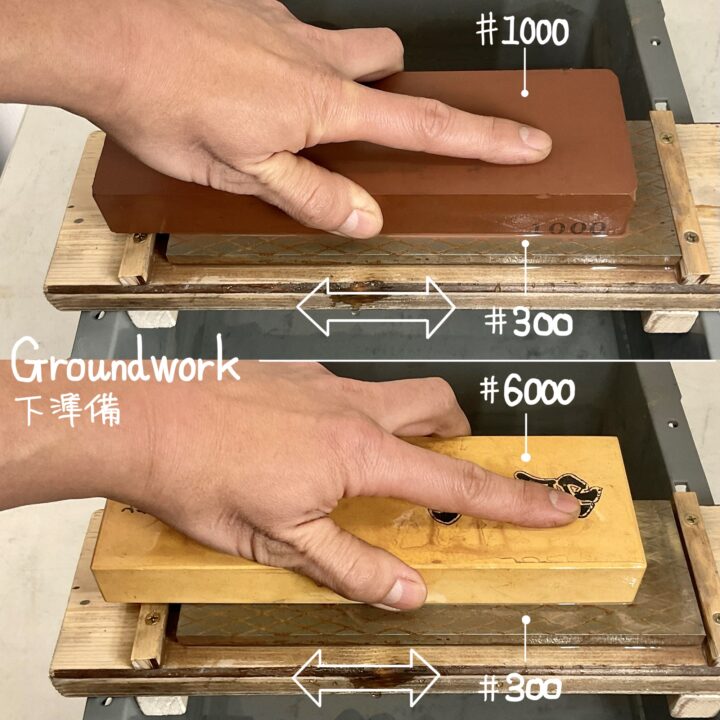

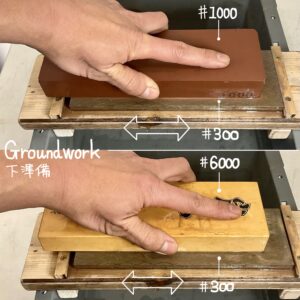

【Skiving Knife blade sharpening setup】

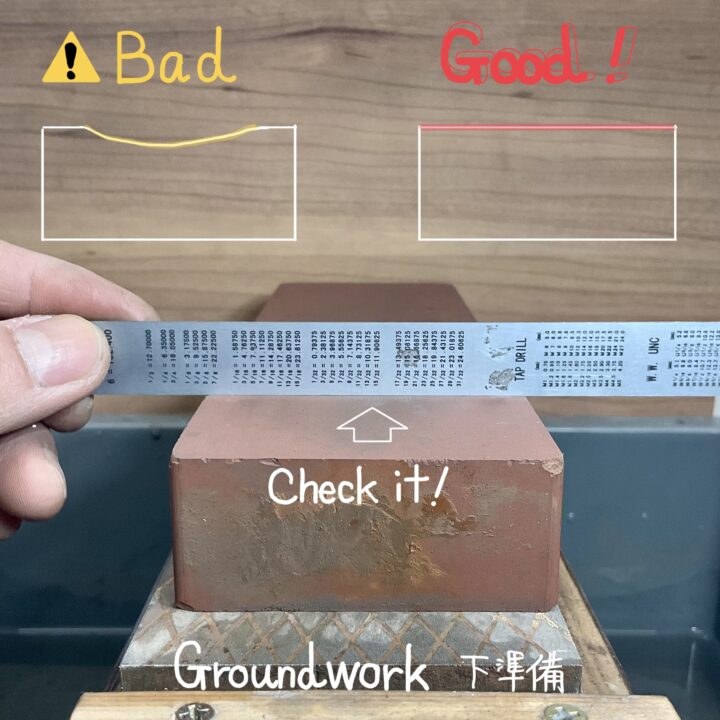

(1) Flattening the grinding stone(13th and 14th images)

(2) Sharpening the back side of the skiving knife(2nd and 3rd images)

(3) Sharpening the surface of the skiving knife(5th, 6th, and 7th images)

(4) Final burr removal of the blade edge(11th image)

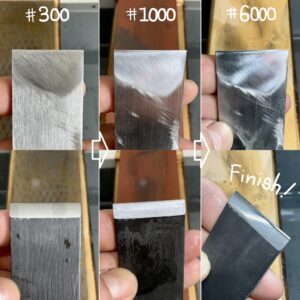

Repeat steps (2) and (3) while changing the sharpening stone (#300→#1000→#6000)

(9th image)

・

【Blade sharpening tips】

(1) Flatten #1000/ #6000 with #300 before sharpening the blade.

Please do each side 15~20 times as a set.

Flattening the whetstone is the most important aspect of blade sharpening.

No matter how much you sharpen a dented sharpening stone that has been used for a long time, a sharp edge will not be applied properly to the entire surface.

In all blade sharpening, it is important not only to sharpen the blade, but also to sharpen the sharpening stone.

(See 13/14 images)

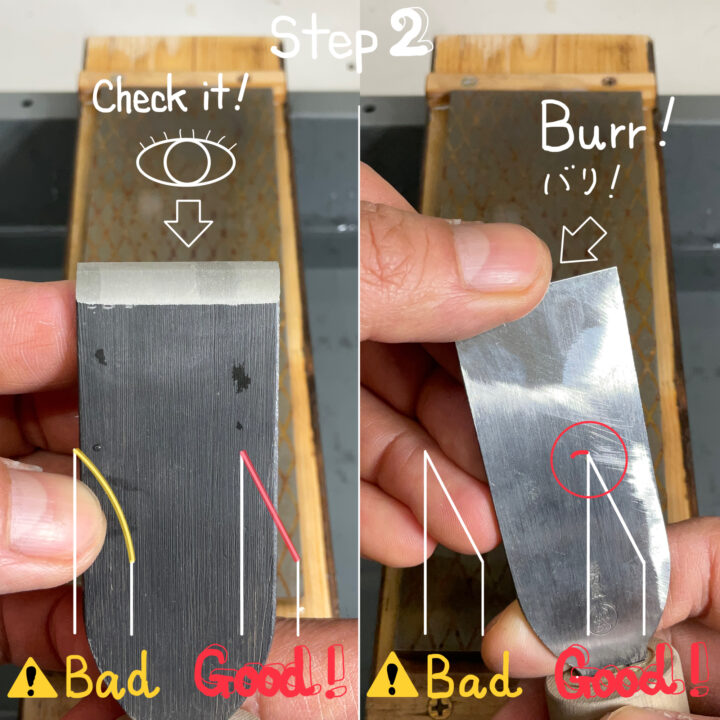

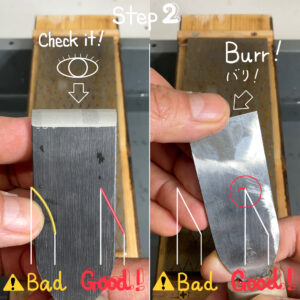

(2) Sharpening back side of Skiving knife

The blade of a skiving knife is first sharpened from the back side.

The rule of sharpening is to sharpen both the front and the back of the knife 5~7 times per set.

After each set, please check the blade [visually] and [check the return of burr with fingertips].

Sharpen the blade with force (80%) on the fingertip of the one closest to the blade edge, and with force when pressing.

No force is applied when returning to the front. (3rd image)

When the sharpening stone reaches the tip of the blade, proceed to step (3). (Fourth image)

If the sharpening stone does not touch the edge of the blade, it cannot be sharply sharpened.

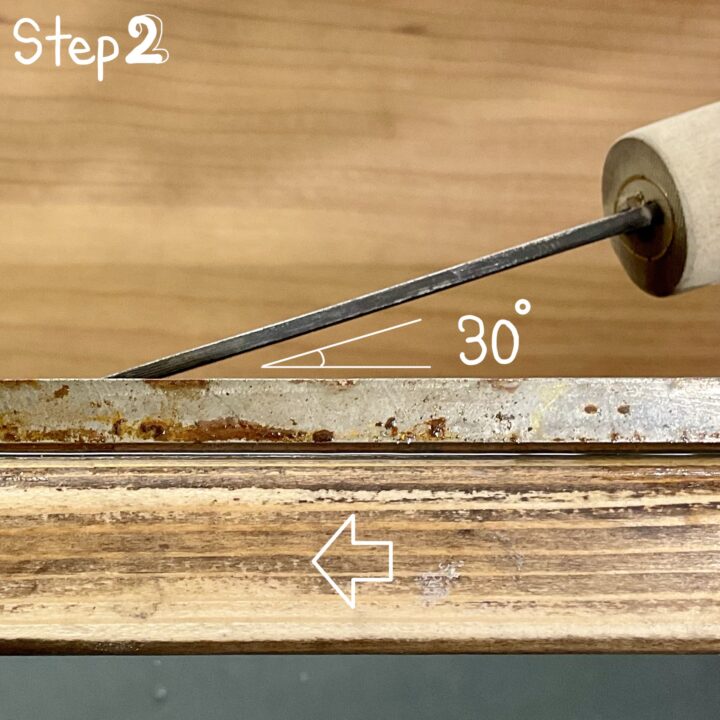

(3) Surface sharpening of Skiving Knife

The position where the skiving knife is pulled toward you is the "starting point" for sharpening. (Please refer to the Instagram video.)

This is the most tricky part.

Anyone can sharpen the knife in a stable manner while keeping the blade edge at 30°. (6th image)

Although this method may seem to vary from person to person, it is actually a method that allows anyone to sharpen a blade at the same angle.

Once the starting point is determined, sharpen the blade while pressing both sides of the blade with the same force.

No force is applied when coming back to the front. (5th image)

【Each time a set of】

Visually check that the grinding wheel is flat against the 30° section.

Check that there is a return on the cutting edge with your fingertip.

Please pay attention to it.

A Burr on the tip of the blade on the reverse side is a sign that sharpening is finished.

Repeat #300→ #1000→ #6000 and #② and #③.

(4) Burr removal of the final blade edge

After sharpening the blade from #300 to #1000 to #6000, gently remove the burr from the back side of the blade of the skiving knife with a towel.

・

【Notes on use.】

+ 3 Sharpening stoneh is Water SherpeningStone. Please use enough water for sharpening.

+ Sharpening stone should be dipped in water only when in use.

After use, wipe off any moisture and store in the shade to dry.

Remaining moisture may cause rust and stains to adhere.

+ Never use oil.

It may cause clogging.

+ Use on a flat surface to prevent the sharpening stone from moving.

Use a towel and sharpening stone stand.

+ Do not rinse off the [sharpening water] that comes out when using #1000/#6000.

Please sharpen with a small amount of water so that the sharpening stone does not dry out.

Sharpening water is a lubricant for blade sharpening.

+ Please rinse off the sharpening water that comes out when using [#300] and sharpen.

The water from #300 is not good for the blade attachment because of the coarse particles of the sharpened metal.

Usage & Maintenance

-

User's Manual

-

Related items

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661