Stitching Groover

Item Name

Stitching Groover

Size

Total length 135mm

Use

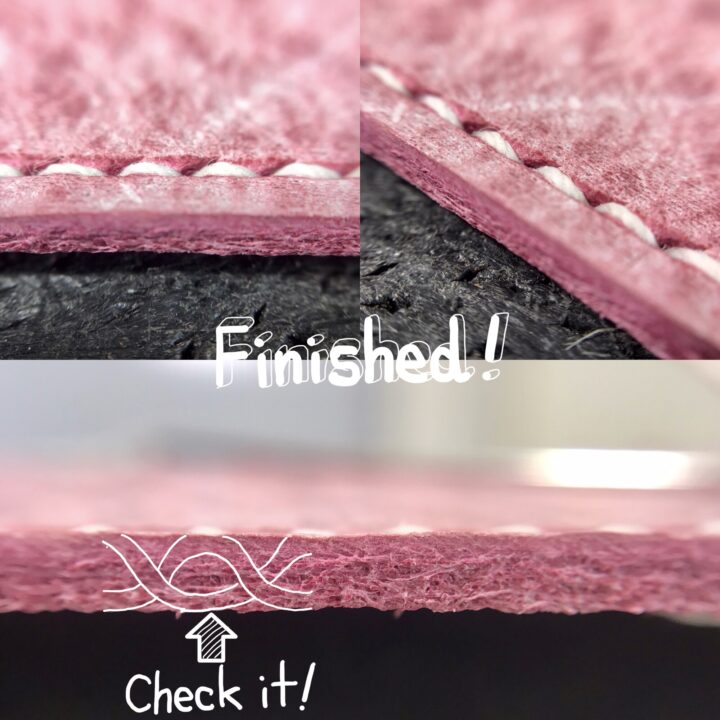

Making a groove on leather sheet to sink a thread when you stitch leather.

Characteristics

Most older conventional stitching groover’s blade didn’t cut well and weren’t treated with rust-proof process so the whole blade part become rusty and you couldn’t use it. The recognition of Stitching groover has been commonly accepted on the market, especially by beginners.

We aimed to improve all the disadvantages and create a tool that anyone can use successfully and for a long time.

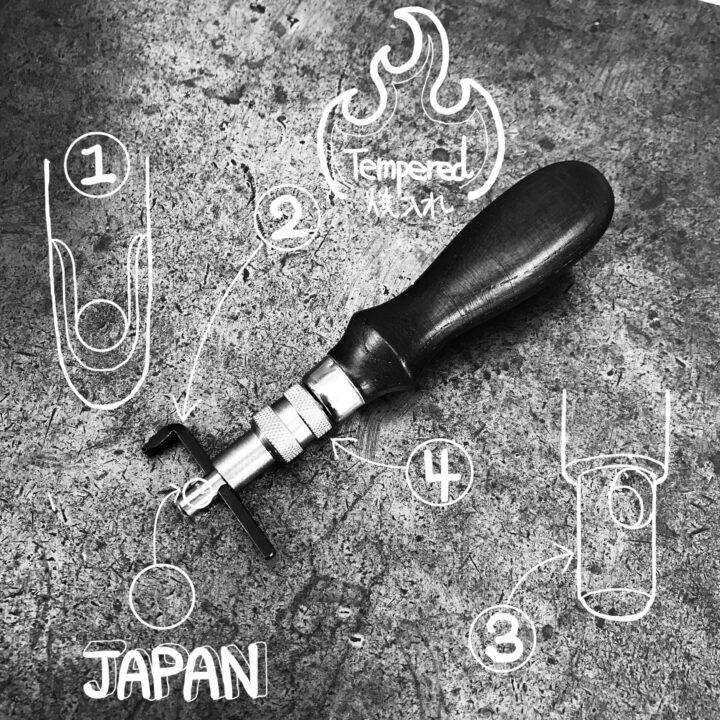

Here are the key points in the development process.

(1) All the blades are assembled by test cutting with leather.

(2) After cutting, a tube is attached to the blade to protect it while it is at its sharpest.

(3) The entire blade should be coated with black coating to prevent rust.

(4)The width of the non-slip part of the body should be thicker.

The body should be thickened so that it can be fixed securely with less force.

(5) The shaft of the body should be made of hard steel.

The blade should not form a square shape due to the force when it is fixed.

① Our artisan sharpens the blades on a one by one basis and tests them on leather sheets, to make sure that it cuts very well.

We ship the tools, putting oil on to the blades to prevent rust and cover it with a vinyl tube to protect it.

② Tempered whole blade, black coating prevents rust.

③ Using hard material with the central shaft so as not to damage the horizontal hole of the shaft when pushing it with the corner of the blade part when you fix it.

④ Knurling the outer part makes it nonslip when you turn it to fix the blade part. Plating the whole tool prevents rust.

⑤ Engraving “JAPAN” which is the country it is made in.

Maintenance

Please keep the tool in good condition by putting oil on the blade part.

Please refer to the Instagram video/website banner on usage and maintenance for instructions on sharpening blades.

If you can’t sharpen the blade well, you can use our “Resharpen blade business”.

(“Resharpen blade business” is mentioned in OKA

FACTORY’s 4 commitments)

Usage & Maintenance

User's Manual

Related items

Please feel free to inquire about anything and also asking for quotations.

Oka Factory & Co.,Ltd.

272-0827 5-10-7, Konodai, Ichikawa-city, Chiba

Monday - Friday, 8:30 a.m. - 6:00 p.m.

FAX +81-47-713-8661